Here at Gesso & Bole we pride ourselves on our one-of-a-kind custom picture frames and we want you to know how we do it!

Here is a detailed breakdown of how me made a recent solid maple frame for one of our customers.

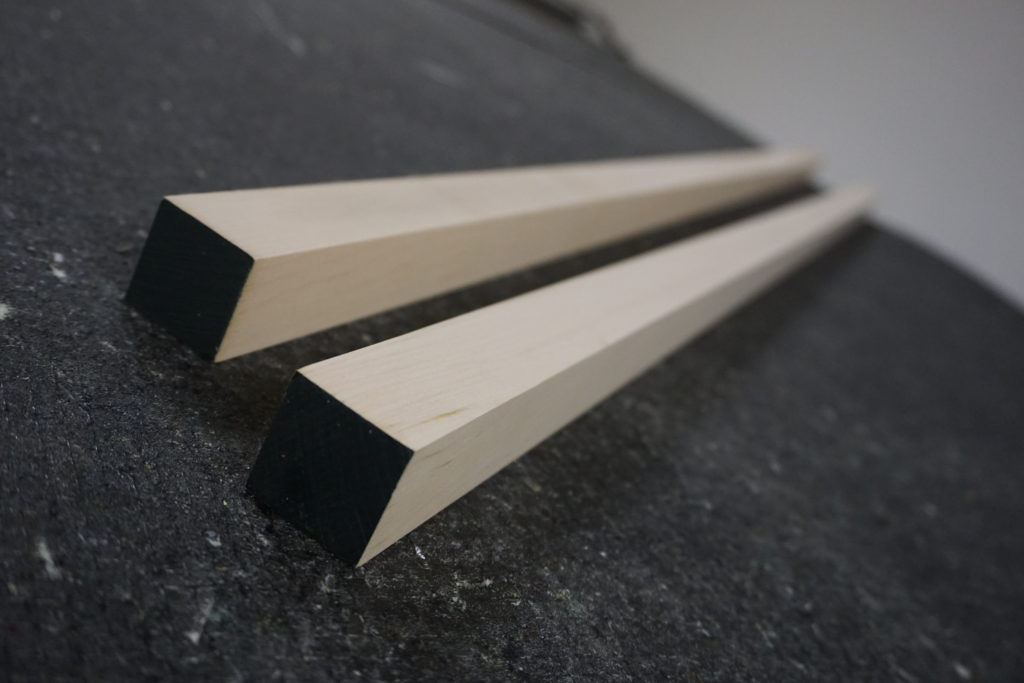

First we carefully selected only the finest locally sourced lumber. For this particular job we used a couple of beautiful pieces of raw maple

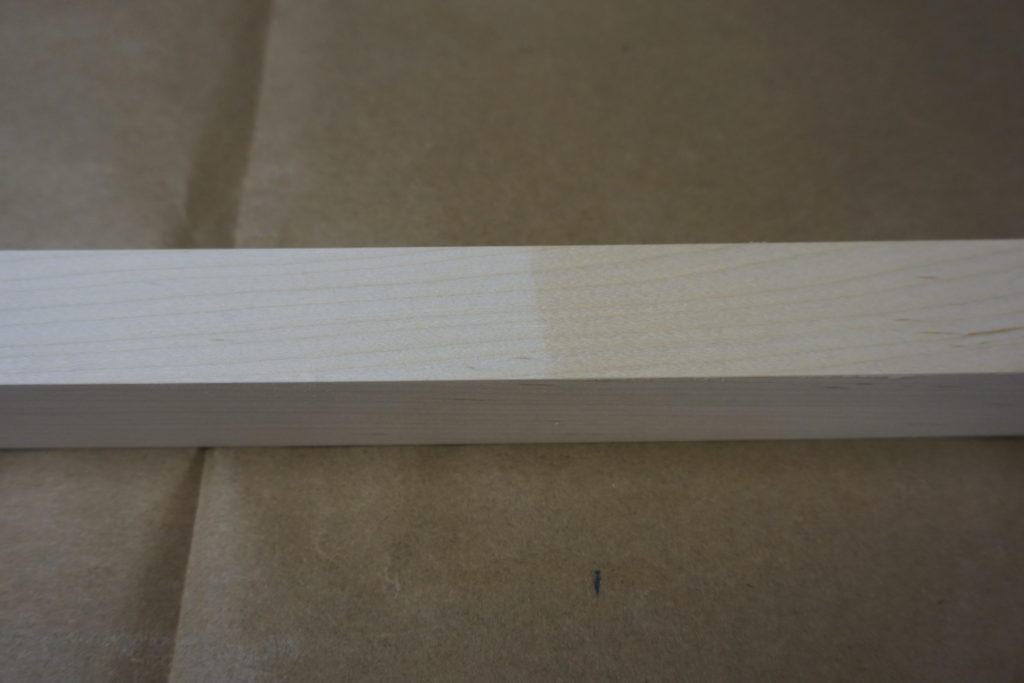

We then created the moulding out of the lumber to the desired height and width. The rabbet was then added for the glass, artwork and backing to fit in

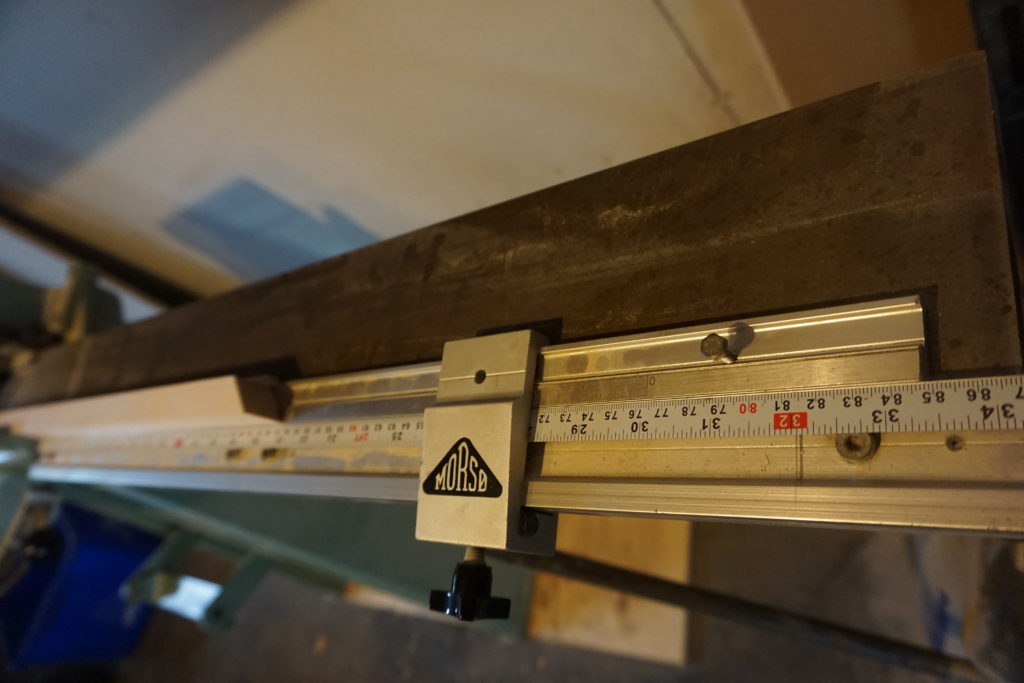

The moulding was into the correct lengths using our Morso mitre guillotine. This machine allows us to cut moulding to a tolerance of less than 1/25″ (1mm)

The cut moulding was then glued and joined together using our underpinner. The underpinner drives metal v-nails into the wood from underneath creating a tight, solid and stable joint.

The frame was then sanded with 3 different grades of sandpaper to ensure a perfectly smooth finish.

We then applied the chosen finish to the wood

And when dry, we buffed and polished the wood to produce a beautiful finish

Next, the glass was cut, cleaned and inserted into the frame

The window mat, undermount and backing board were then cut and the artwork was hinged to the undermount and inserted into the frame.

Compressed air was used to clean off any dust or foreign particles that have settled onto the glass, artwork or mat. The frame was then sealed and backed with paper. Hangers and wire were attached so that the framed artwork can be displayed on the customers wall.

The whole process of making a completely handmade frame can take anywhere from a couple of hours to a couple of days depending on the moulding and finish chosen.

Recent Comments